Aramith phenolic resin : why it makes the difference !

Heavy duty design

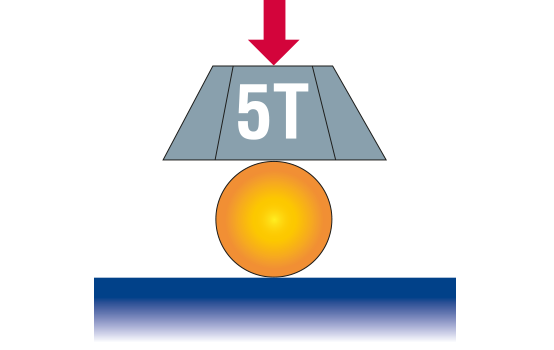

Rather than a number-plug-design, the Aramith concept has the numbers precision-engraved in a solid core that runs all the way through the ball. As such, it is impossible for number-cores to fall out over time. Using phenolic resin assures homogeneous characteristics and perfect chemical bond between each ball part. So homogeneous that when finally getting to its breaking point (and one needs minimum a 5 ton-load in case of an Aramith ball), the ball will break up totally at random, and not along the parting line between the stripe and the rest of the ball, as one would fear.

Burn-spot resistant

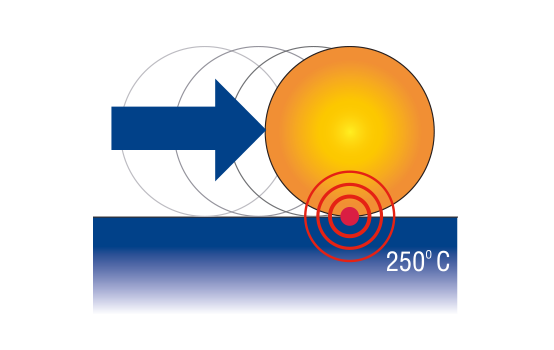

Hitting a cue ball actually accelerates it from 0 to over 30 km/h (20 MPH) in just a fraction of a second. The resulting friction temperature between ball and cloth can easily reach 250°C (482°F). That’s why Aramith balls are the only ones made from genuine phenolic resin : their molecular structure is engineered to be wear resistant at these high temperatures, making Aramith balls far less vulnerable to abrasive burn-spots. They hold their high luster and smoothness over a much longer period of time, resulting in minimal ball and table cloth wear.

High impact resistance

Because hitting the balls is the essence of the billiard game, impact resistance is a critical factor. Aramith phenolic heat-curing process fully stabilizes material tensions. It produces a vitrified high-density surface that offers maximum impact resistance. Tests show Aramith phenolic balls to withstand to over 50 times more impacts than other phenolic or polyester balls. They are also twice more scratch-resistant.

Consequently, when intensively used even on less maintained tables, Aramith balls are clearly far less easily damaged than others by pocket fixings, table mechanisms or cue stick tips..