Aramith quality is a tradition

The quality of the raw materials is vital to guarantee high performances from a skittle ball. That is why Saluc only uses Aramith phenolic resins produced in its own installations. It totally masters the technical specifications of the materials that are so important for the quality of play.

Producing a quality skittle ball takes 14 days and requires numerous processes such as moulding, baking, grinding and polishing – all carried out with state-of-the-art techniques. As well as being automatically controlled to ensure compliance with the tightest specifications, each ball is also checked by a specialized operator before leaving the factory.

Throughout the fabrication, computer technology combined with the work of true craftsmen guarantees diameter and roundness within very precise tolerances for each ball.

Quality also implies respect of the environment with the combination of ecological processes and advanced recycling technology.

Aramith phenolic resin : the big difference !

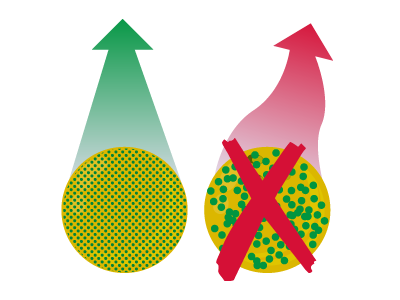

Balance

Balance and constant density are indispensable for controlling speed, direction, rotation and impact. The only resin totally free of particles (no foreign bodies in the resin), Aramith phenolic resin offers the unique benefit of perfect homogeneity and density. As the centre of gravity is in the perfect centre of the ball, the balance needed for precision is guaranteed.

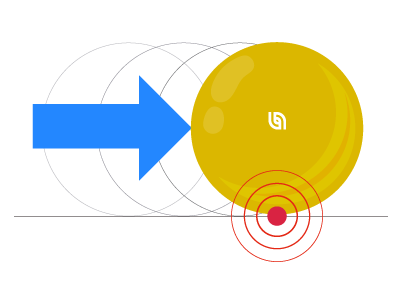

Resistance to friction

When it is thrown, the ball actually glides on the lane for a time before rolling. To resist the high levels of friction, Aramith balls are made in genuine phenolic resin. Its chemical structure is particularly well adapted to resist the resulting abrasion and heat. So the balls preserve their beauty and hold, while causing less wear on the lane.

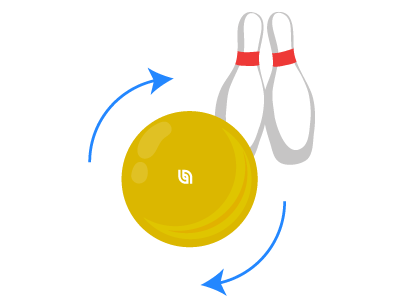

Excellent hold

To stabilize the Aramith resin, it is baked until hard. This creates a high-density vitrified surface. That is why Aramith balls offer a very effective hold that is appreciated by players that like to perfectly master their throw.

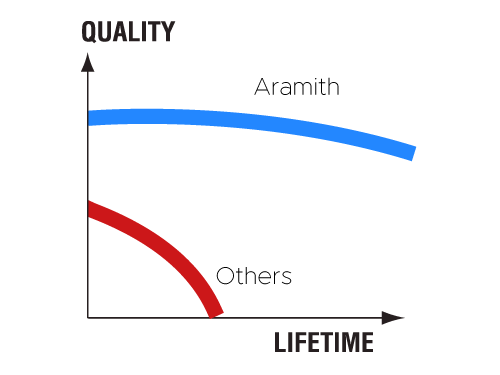

An intelligent investment

- Invest in quality

Aramith phenolic resin skittle balls have a playing life 5 times longer than other polymer or polyester balls.

- Invest in economy

The specific structure of Aramith phenolic resin makes the surface highly resistant to friction, so reducing possible scratches both on the ball and on the lane. What’s more, Aramith balls underline the quality image of your club. They help beginners and regulars to improve performance, so you enjoy your game more and make progress.

Aramith balls are recognized by the engraved logo.

The Aramith brand and logo are registered trademarks of SALUC SA.

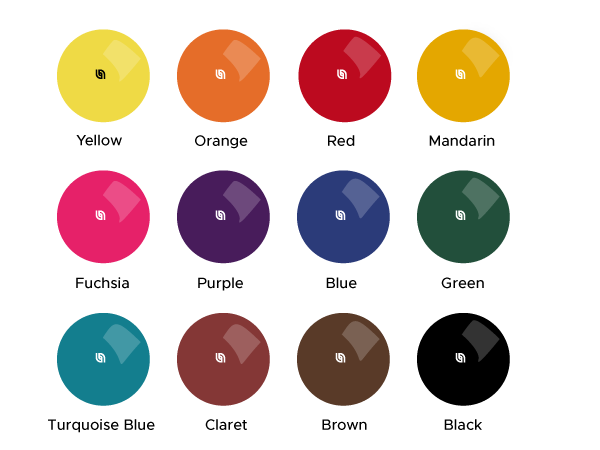

Aramith Colour Range

Available in diameters : 120, 140, 150 and 160mm.

Cleaning products

In 3 minutes, enjoy exceptional hold thanks to our cleaning product and cloth!

- Tested by professional players

- Exclusive, there’s nothing else like it on the market!

- Developed by our own research team.

The cleaning product gives a shine without sticking to the ball and gives the ball extra hold without leaving a deposit on the ball or the lane. Antistatic and non-toxic, it is easy to use.

The cloth is used dry or with the product. Its microfibre structure, developed for a deeper clean, absorbs any traces of grease and liquid. It offers easy upkeep and is guaranteed for a long lifetime.